There are two types of EV charging stations – AC Charging Stations, DC Charging Stations. While EVs always accept DC charge, they generally have an onboard charger to convert AC power to DC power. The other way to charge the vehicle is by directly plugging into DC Fast Charger. DC charging stations convert AC power to DC before it reaches the vehicle. As the current is already converted to Direct Current from Alternating Current, it is possible to deliver more power, faster. So, DC chargers are used mainly for fast charging of the Electric Vehicles. DC stations can provide upto 350 KW of power and fully charge an EV within 15 minutes. Due to their fast charging capabilities, DC fast chargers are ideal for short-stop locations, fleet vehicle charging, buses & trucks charging.

In this article we shall look into the following – (a) What are the key components of a DC fast charger (b) What types of connectors are used for DC fast charging (c) What are the limitations of DC fast charging.

Key components Of DC Fast Charger

DC Fast Chargers typically operate at Level 3 charging powers and are designed to charge electric vehicles quickly with a power output ranging between 50 KW and 350 KW. Due to higher power operations, AC to DC converter, DC to DC converter and power control circuits become larger and more expensive. This is why DC chargers are operated as offboard chargers rather than onboard chargers.

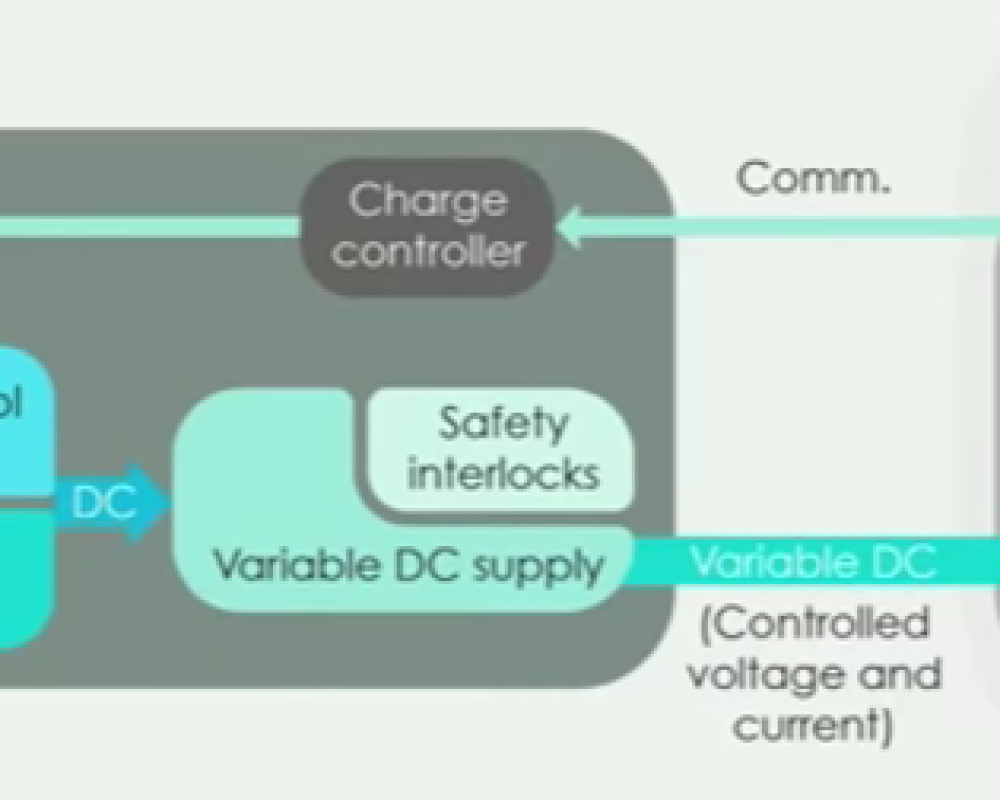

In the first step, the alternating current provided by AC grid is first converted into Direct Current using a rectifier inside the DC charging station. Then the power control unit appropriately adjusts the voltage and current of the DC converter to control the variable DC power delivered to the battery. There are safety interlocks to deenergize the charging to protect the EV battery in case of some power fluctuations.

The battery management system (BMS) present alongside the battery in the car communicates regularly with the charger and ensures optimal charge is delivered to the vehicle. Whenever there is a fault condition or improper connection between charger and vehicle, BMS shall communicate and stop the charge. CAN (Control Area Network) & PLC (Power Line Communication) are used for communication between charger and the vehicle.

Now that we have looked into how DC charger works, let us look at various DC fast charger connector types.

DC Fast Charger Connector Types

There are around 5 different DC fast charger connector types – CCS US, CCS Europe, Chademo, Tesla US/EU, China GB/T Standard. CCS (Combined Charging System) is primarily used by USA vehicles. CCS 2 is primarily used in Europe. Chademo is used globally for cars manufactured by Japanese companies, Tesla US/EU is used for Tesla vehicles and finally China GB/T standard is a standard used primarily in China. Let us now look these chargers one by one.

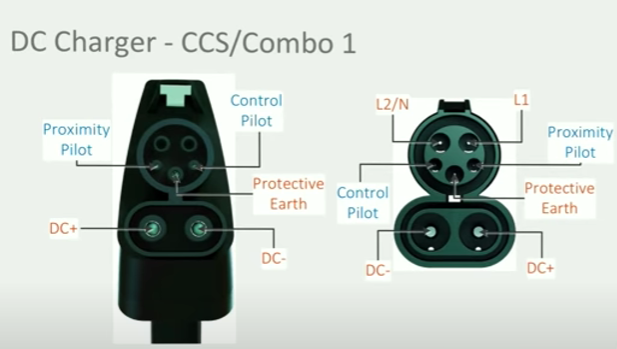

Combined Charging System (CCS 1)

Combined Charging System (CCS1) are interconnected chargers for both AC & DC chargers. They are derived from Type 1 & Type 2 connectors for AC charging by adding two extra pins for high current DC charging. The connectors derived from Type 1 & Type 2 are respectively called as COMBO 1 & COMBO 2.

CCS / Combo2

Similarly CCS/Combo 2 connectors are derived from AC Type 2 connectors and retain the earth pin and two signal pins, namely the control pilot and proximity pilot. 2 DC power pins are added at the bottom of the connector for high power DC charging. Similarly on the vehicle inside, the upper part facilitates the AC charging from 3 Phase AC and bottom part has DC charging. CCS combo chargers can deliver max current of upto 350 A and voltage range of 200 – 1000 V giving a maximum power of 350 KW.

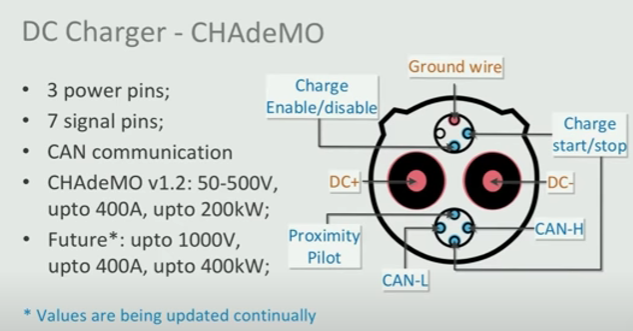

CHAdeMO

The third DC charger type is the CHAdeMO connector which is a Type 4 EV connector. It has 3 power pins and 6 signal pins for its operation. The CHAdeMO uses Control Area Network or CAN protocol in the communication pins for communication between the charger and the car. A control area network communication is a robust vehicle communication standard designed to allow micro controllers and devices to communicate with each other in real time without a host computer. As of now, voltage, current and power levels of CHAdeMO are ranging from 50 – 500 V with a current upto 400 A thus providing a peak power of upto 200 KW of charging. In the future, it is expected that upto 1000 V, upto 400 A, upto 400 KW of charging is facilitated by CHAdeMO.

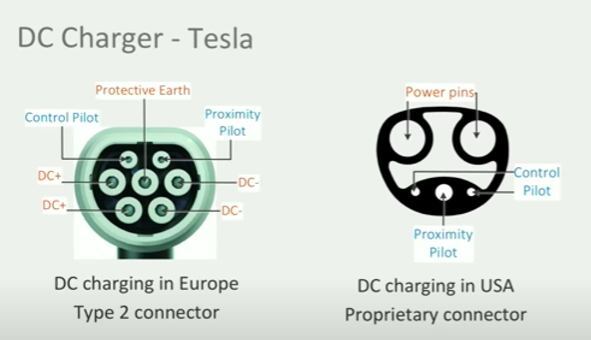

Tesla DC Charger

Unique feature of TESLA connector is that same charger can be used for both AC charging and DC charging. TESLA now offers DC charging upto 120 KW and this is expected to increase in the future.

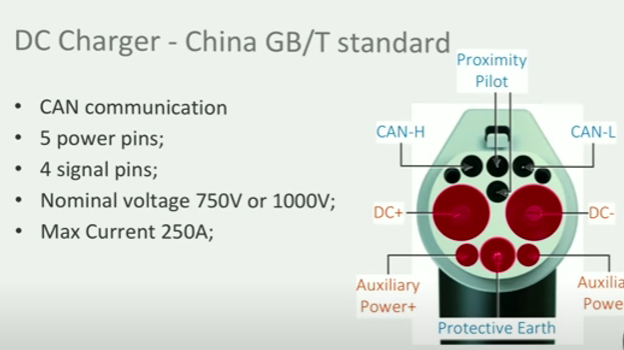

China GB/T Standard

Finally, China has its own DC charging standard and connector that uses CAN BUS for communication. It has 5 power pins, 2 for DC power, 2 for low voltage auxiliary power, 1 for ground and 4 signal pins, 2 for proximity pilot and 2 for control area network communication. As of now, the nominal voltage used for this connector is 750 V and max. current 250 A.

Limitations of DC Fast Charging

Fast charging power can’t be used for infinite. This is due to 3 technical limitations. Let us look into these 3 technical limitations of DC fast charging.

First limitation is high current charging leads to high overall losses both in charger and battery.

Second major limitation is coming from the battery. When fast charging a battery, the SOC of battery can go upto 70% to 80%. This is because fast charging creates a lag between voltage and SOC and this phenomenon increases as the battery is being charged faster. Hence, fast charging is typically done in the constant current (cc) region of the battery. After that, charging power is reduced gradually in the constant voltage or CV charging region.

Third limitation is due to the charging cable. For any charger, it is important that the cable is flexible and lightweight. For higher charging powers, thicker cables are required to allow more charging current else it will heat up due to current. For charging current of 250A and above, cables become very thick and unmanageable.